bluesoverlord

TDPRI Member

I'd like to get everyone's idea of different truss rod designs work. I'll tell you mine, then I'd like you to fill in any holes in my knowledge base.

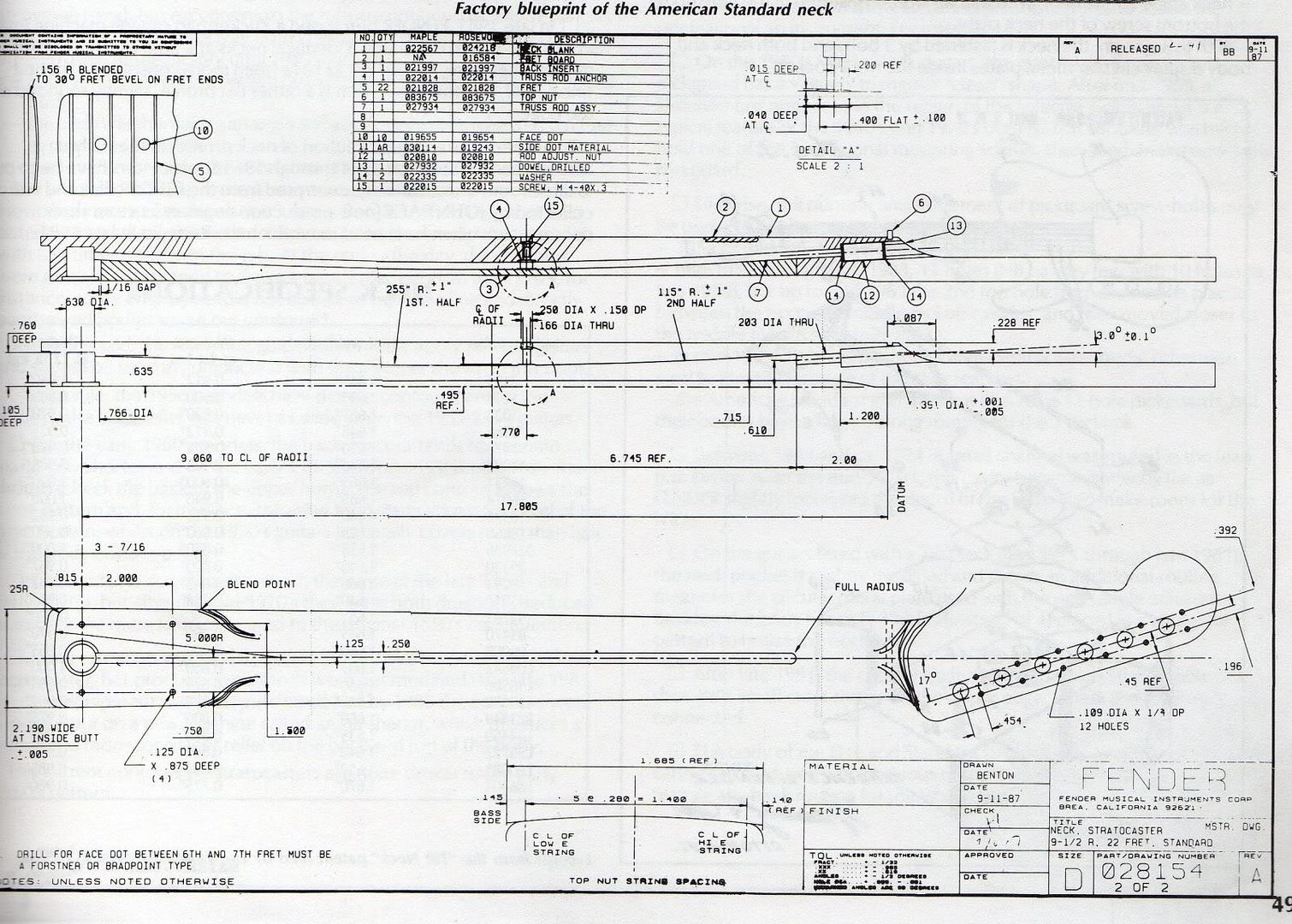

When I first read about truss rods the explanation said that the bow in the rod was in the same direction as the force you want to exert. So, if the rod is bowed toward the back of the neck the neck will pull backward and, thus, against the pull of the strings. The reasoning was that the rod "wants to straighten out." I couldn't get my mind around that at all, especially when I started to work with this thin piece of steel. This explanation was useful for remembering how to put the rod in and which way to turn in, but it was just the plain wrong way to explain the physics of the rod. I find that if I don't understand the mechanism I wont be happy.

So......I read further. I found something that made more sense (for a single rod). The explanation was that the as the nuts are tightened the neck wood is put in compression between those two points. The neck yields where the wood goes in to compression. The real understanding comes into why the back of the neck yields. And the next question is why the rods have to be shaped the way they are in certain guitars (if they really do). And where on the axis of the neck should the rod be placed.

Now, the way I understand it is that when a rod is placed toward the back of the neck (away from the fretboard) it will compress the back wood more than the front and produce backbow. A single rod placed in this position can only do this one thing. So, if that is true, then a rod could theoretically be placed in the back of a neck for its whole length. Does this mean it can be straight? And then could make the access on the back of the headstock if you wanted? The problem here is that my mind then wants me to believe that bow would be created in the direction of the front of the neck. Actually if I think of it on a very small scale, I think of the first molecule of a turn that bends the rod EITHER way and the smaller amount of wood on the back of the neck would yield. And if we kept going and the rod never broke, would the neck backbow and thus take the rod with it into a backbow (assuming the fibers of wood had infinite compression without fracturing)?.

Now the other thing that got me thinking about this is the format of of the channel in other guitars like Les Pauls, or even a Benedetto. The LP has a straight channel (at least it does in Gil's build...this is where I got thinking about this stuff), but it is angled towards the back of the neck and puts the back of the neck in compression. Which way would the rod bow if it went out to infinity in compression? The LP proves you don't have to start out with a bow if the position of the rod is correct.

Benedetto likes a little curve at the upper one third of the neck, but straight towards the body. Those rods have their axis towards the back of the neck.

So....you can have a straight single rod behind the mid axis of the neck and get back compression, therefore, back bow. Not sure which way the rod would bend.

You can have a bowed rod with most of its mass behind the mid axis of the neck.

This brings us to dual rods. This to me CAN work on the same principle of compression of the neck, but can do it in either direction. If the rods are placed centered around the mid axis of the neck, the work they must do to compress the wood in either direction is equalized. If I move the rod toward the back the compression of the back wood (less mass) becomes easier and the power needed to backbow would become less. However, it seems to me that the power needed to frontbow would increase. If you moved the rod toward the front (fingerboard) the opposite would be true.

What do I get from all of this?

If I choose a single rod system, the rod will only apply backbow forces to counter the strings. The further back (deep) the rod is the less work it must do because it is compressing a smaller amount of wood. It doesn't need to start of with a bow (correct?). It could be accessed on the back of the headstock if you wanted (correct?).

If I choose a double rod system, the rod can bow either way, so its best to keep it as close to center as possible if you EXPECT to need backbow and possibly frontbow during the life of the guitar, e.g., heavy strings changed to light strings, humidity changes, age, etc. However, it seems to me that the double rod could still be placed deep because the power NEEDED to frontbow would be SHARED by the rod and the strings. Therefore they could more easily compress more wood on the front. The trick is to know where that balancing point is.

I hope all that made sense....OR.....that someone can at least set me straight.

Thanks,

When I first read about truss rods the explanation said that the bow in the rod was in the same direction as the force you want to exert. So, if the rod is bowed toward the back of the neck the neck will pull backward and, thus, against the pull of the strings. The reasoning was that the rod "wants to straighten out." I couldn't get my mind around that at all, especially when I started to work with this thin piece of steel. This explanation was useful for remembering how to put the rod in and which way to turn in, but it was just the plain wrong way to explain the physics of the rod. I find that if I don't understand the mechanism I wont be happy.

So......I read further. I found something that made more sense (for a single rod). The explanation was that the as the nuts are tightened the neck wood is put in compression between those two points. The neck yields where the wood goes in to compression. The real understanding comes into why the back of the neck yields. And the next question is why the rods have to be shaped the way they are in certain guitars (if they really do). And where on the axis of the neck should the rod be placed.

Now, the way I understand it is that when a rod is placed toward the back of the neck (away from the fretboard) it will compress the back wood more than the front and produce backbow. A single rod placed in this position can only do this one thing. So, if that is true, then a rod could theoretically be placed in the back of a neck for its whole length. Does this mean it can be straight? And then could make the access on the back of the headstock if you wanted? The problem here is that my mind then wants me to believe that bow would be created in the direction of the front of the neck. Actually if I think of it on a very small scale, I think of the first molecule of a turn that bends the rod EITHER way and the smaller amount of wood on the back of the neck would yield. And if we kept going and the rod never broke, would the neck backbow and thus take the rod with it into a backbow (assuming the fibers of wood had infinite compression without fracturing)?.

Now the other thing that got me thinking about this is the format of of the channel in other guitars like Les Pauls, or even a Benedetto. The LP has a straight channel (at least it does in Gil's build...this is where I got thinking about this stuff), but it is angled towards the back of the neck and puts the back of the neck in compression. Which way would the rod bow if it went out to infinity in compression? The LP proves you don't have to start out with a bow if the position of the rod is correct.

Benedetto likes a little curve at the upper one third of the neck, but straight towards the body. Those rods have their axis towards the back of the neck.

So....you can have a straight single rod behind the mid axis of the neck and get back compression, therefore, back bow. Not sure which way the rod would bend.

You can have a bowed rod with most of its mass behind the mid axis of the neck.

This brings us to dual rods. This to me CAN work on the same principle of compression of the neck, but can do it in either direction. If the rods are placed centered around the mid axis of the neck, the work they must do to compress the wood in either direction is equalized. If I move the rod toward the back the compression of the back wood (less mass) becomes easier and the power needed to backbow would become less. However, it seems to me that the power needed to frontbow would increase. If you moved the rod toward the front (fingerboard) the opposite would be true.

What do I get from all of this?

If I choose a single rod system, the rod will only apply backbow forces to counter the strings. The further back (deep) the rod is the less work it must do because it is compressing a smaller amount of wood. It doesn't need to start of with a bow (correct?). It could be accessed on the back of the headstock if you wanted (correct?).

If I choose a double rod system, the rod can bow either way, so its best to keep it as close to center as possible if you EXPECT to need backbow and possibly frontbow during the life of the guitar, e.g., heavy strings changed to light strings, humidity changes, age, etc. However, it seems to me that the double rod could still be placed deep because the power NEEDED to frontbow would be SHARED by the rod and the strings. Therefore they could more easily compress more wood on the front. The trick is to know where that balancing point is.

I hope all that made sense....OR.....that someone can at least set me straight.

Thanks,