MBolanlovechild

TDPRI Member

I have a very basic understanding of valve amp electronics, though I've recently bought the very recommended 'Building Valve Amplifiers' by Morgan Jones and am slowly reading through it, so far it has proved very helpful. My building experience goes as far as a fuzz face clone which I managed to put together once with no problems, although that was a kit..

Unfortunately I am now living amongst other human beings whom share the ability to hear, so I would benefit from a small portable low-wattage amp. Something akin to the little giant would be ideal. I've been lucky enough to try one out in a store and it does produce a lovely sound, however, they're becoming more and more collectible and its getting hard to find any for a fair price; so I thought, it looks like as simple a circuit design as any, why not try building one.

So where to begin, I guess I should start with my plan for the enclosure then move from there to the main layout. I want it to resemble the original in so far as it is compact, but I hear that some people feel the 6 or 8" speaker is a shortcoming. I suppose if I put together the amp before the cab I could run it out to a cabinet and test different speakers before I make a decision.

http://www.vintagehofner.co.uk/gallery/gallery3/gallery4/lgi2.jpg

I've always thought that the layout was a bit precarious, and was done in this way for cost-effective reasons and to accommodate the wider less deep 'radio' style shape.

I prefer the shape and layout of something like the premier 50, which has the chassis on the floor of the amp with tubes mounted upwards.

(link removed)

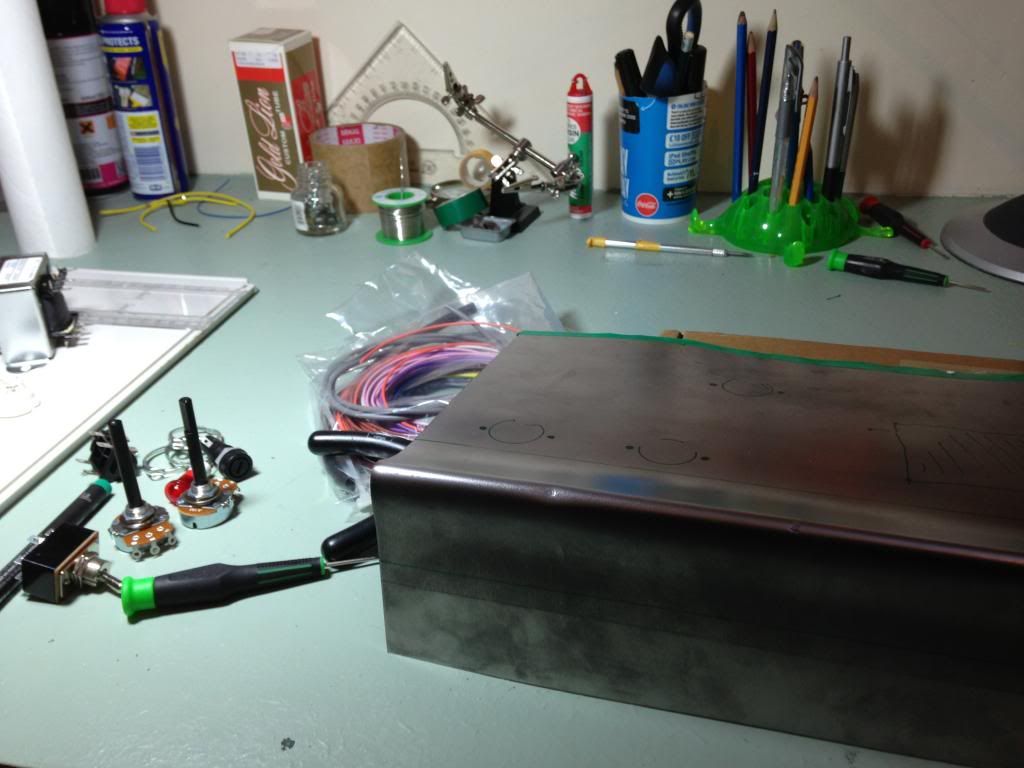

I imagine that the simplest way of building the circuit would be to use turret board. Just to note, I will try to outline everything I decide to do, no matter how simple it is because i'm likely to make a blinding mistake, so when I say 'i'll mount the tube sockets to the metal chassis', I don't think that would be necessarily controversial, I just don't want to take anything for granted for risk of error. If I do end up putting the chassis on the floor of the amp, then I suppose the output and power transformers can be fixed to the top of the metal chassis. I'd like to have the control panel on the top, or I could mount all of them on a backplate which would make for simpler construction and shorter wire runs. But I think this can be left for later.

Here is the circuit diagram I plan to use

http://www.vintagehofner.co.uk/britamps/selmer/schematic/lgmk3.html

I'll be sourcing most of my parts from ampmaker.com (link removed) , seems to stock most of the things I need, and the prices seem fair.

When it comes to buying caps, how do I decide on the wattage required for each? Also, are there any hard fast rules for which types of resistors are best for certain uses?

I figured that I would start by selecting the transformers first, would these two be suitable?

(link removed)

(link removed)

Unfortunately I am now living amongst other human beings whom share the ability to hear, so I would benefit from a small portable low-wattage amp. Something akin to the little giant would be ideal. I've been lucky enough to try one out in a store and it does produce a lovely sound, however, they're becoming more and more collectible and its getting hard to find any for a fair price; so I thought, it looks like as simple a circuit design as any, why not try building one.

So where to begin, I guess I should start with my plan for the enclosure then move from there to the main layout. I want it to resemble the original in so far as it is compact, but I hear that some people feel the 6 or 8" speaker is a shortcoming. I suppose if I put together the amp before the cab I could run it out to a cabinet and test different speakers before I make a decision.

http://www.vintagehofner.co.uk/gallery/gallery3/gallery4/lgi2.jpg

I've always thought that the layout was a bit precarious, and was done in this way for cost-effective reasons and to accommodate the wider less deep 'radio' style shape.

I prefer the shape and layout of something like the premier 50, which has the chassis on the floor of the amp with tubes mounted upwards.

(link removed)

I imagine that the simplest way of building the circuit would be to use turret board. Just to note, I will try to outline everything I decide to do, no matter how simple it is because i'm likely to make a blinding mistake, so when I say 'i'll mount the tube sockets to the metal chassis', I don't think that would be necessarily controversial, I just don't want to take anything for granted for risk of error. If I do end up putting the chassis on the floor of the amp, then I suppose the output and power transformers can be fixed to the top of the metal chassis. I'd like to have the control panel on the top, or I could mount all of them on a backplate which would make for simpler construction and shorter wire runs. But I think this can be left for later.

Here is the circuit diagram I plan to use

http://www.vintagehofner.co.uk/britamps/selmer/schematic/lgmk3.html

I'll be sourcing most of my parts from ampmaker.com (link removed) , seems to stock most of the things I need, and the prices seem fair.

When it comes to buying caps, how do I decide on the wattage required for each? Also, are there any hard fast rules for which types of resistors are best for certain uses?

I figured that I would start by selecting the transformers first, would these two be suitable?

(link removed)

(link removed)