skitched

Tele-Meister

...that worked well? Just curious if anyone has seen a plywood neck. I’m guessing it would need a few hundred layers of poly to ensure it didn’t embed splinters in your palm thou...

...that worked well? Just curious if anyone has seen a plywood neck. I’m guessing it would need a few hundred layers of poly to ensure it didn’t embed splinters in your palm thou...

That’s how skateboards are laid up...

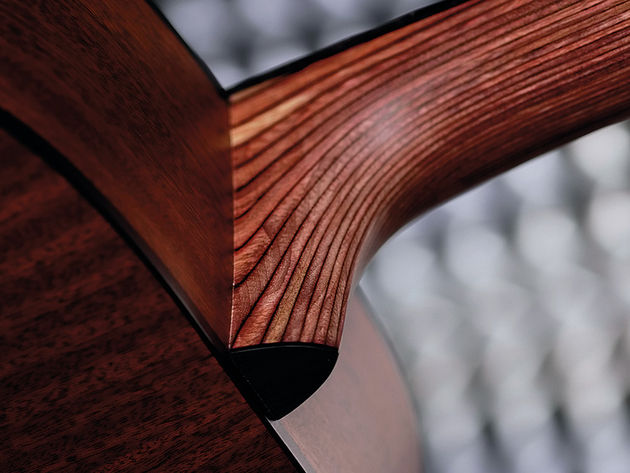

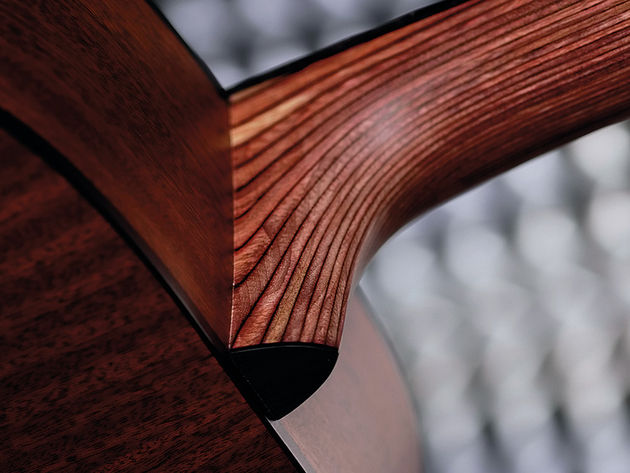

These colors are created by gluing a number of pre stained wood pieces together.

.

I bought my wife one of the X-series guitars for Christmas several years ago and I was going to suggest that as an example. I don't know the process, nor do I know when "plywood" crosses over to become a "gluelam" structure like a support beam or a neck. Plywood is strong enough to be mechanical support beams in home construction, but it also fails when the beam is heated enough to break down the glue (these things have killed more than a couple of firefighters responding to basement fires, etc., as an aside).From what I can tell some of the Martin guitars actually had laminated necks with their stratabond necks.

Zoot Suit SG. Neck is also laminated (plywood).

I'm very excited about the possibilities of bamboo. It seems like a very stable material.

Framus was made by many of the same people who made the Klira, in my post above. If you want to spend a half-hour learning some interesting guitar history, do a Wikipedia search on these brands. The Framus Texan in the Wikipedia photograph is almost identical to my Klira.Framus Acoustics, like the TEXAN model had laminated necks.

I'm very excited about the possibilities of bamboo. It seems like a very stable material.

View attachment 706089

here's an old 70's Klira Bluebell 12-string acoustic, made in Germany. The neck is laminated with a thousand pieces. I had never seen anything like it. It seems to be pretty stable.

there is the possibility that your bass was made by one of the Czech/German companies, and branded with the name "Kingston" because it was cool. I would love to see a picture of it!I have an old Kingston bass sitting in the corner that has a neck exactly like this. I played it for a time with the church band many years ago and it never seemed to have an issue. It's still straight (at least to the naked eye) after sitting in a shed for several years.